Our Philosophy

As a family-owned enterprise, we place quality at the heart of our legacy—both in our products and in our people. Our commitment to excellence has allowed us to craft high-precision watches for over a century, continuously advancing and delivering innovative Swiss Made timepieces.

Swiss Made

Delma’s hometown of Lengnau, near Biel/Bienne, is located at the heart of Switzerland's renowned watchmaking region, spanning from Geneva in the southwest to Basel in the northeast.

Design process

The life of every Delma watch starts with a sketch. The artist’s ideas are then rendered as technical drawings and printed in 3D, generating a realistic model of the future timepiece. Finally, a prototype with the intended materials and surface finishes is created before the design is approved.

Production

Each watch is meticulously assembled by a single skilled watchmaker in our workshop, ensuring the highest level of focus and craftsmanship. The process begins with pairing the dial to its movement, followed by the delicate placement of the hands onto their axles and the careful assembly of the dial. Finally, the complete movement is set into the watch case, the crown is attached, and the case back is securely fastened.

Quality control

We guarantee strict isolation of production and quality control. Every watch is tested by a separate team of specialists ensuring each element is checked at least twice before it leaves our facility. These rigorous tests carefully examine the components of the watch including its functionality, rate, precision, water-resistance and physical appearance.

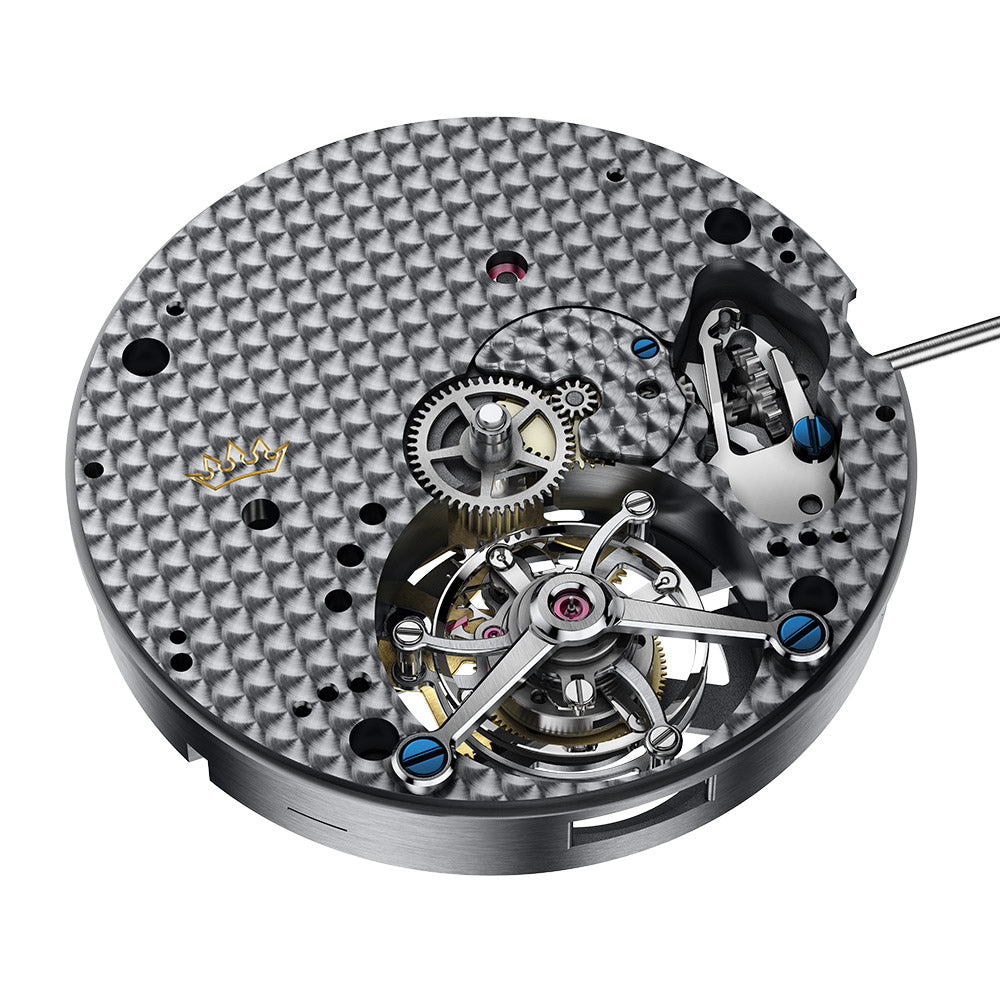

Visible Craftsmanship

Through a transparent case back, we showcase the intricate inner workings and precision engineering of our mechanical watches. The rhythmic motion of the balance wheel and the graceful movements of the oscillating mass in our automatic watches can be admired as they wind with each movement of the wrist.

Finest materials

We only use the best materials available including exclusively single cut, SI-H Wesselton diamonds. The sapphire crystal on all of our watches yields a resilient translucent lens into the timepieces’ intricate details. Our stainless steel watches are constructed from grade 316L steel with a high resistance to scratches and corrosion. Our black models are coated with Physical Vapor Deposition, a specialized method which yields an absolutely even surface. A black Diamond Like Carbon coating is applied to our Shell Star Black Tag for ultimate imperviousness.

Authentic Swiss Components

Our movements are sourced from the most trusted Swiss partners, renowned for their expertise and long-standing heritage. Each timepiece is meticulously assembled in our workshops, adhering to a rigorous process that ensures it meets the high standards required to carry the Swiss Made label.

PERPETUAL INNOVATION

At DELMA, innovation and reliability are at the heart of every timepiece we create. Our dedicated team drives this mission forward, continually refining their expertise through ongoing training and leveraging cutting-edge equipment. By staying at the forefront of industry advancements and collaborating with exceptional partners, we craft timeless watches that not only endure but also adapt to the evolving needs of our discerning clients.